Our easy-to-digest illustrated guide to laser engraving

Laser: originally an acronym for Light Amplification by Stimulated Emission of Radiation when built in 1960 by Theodore H. Maiman at Hughes Research Laboratories. Today, we see lasers used in several things. Compact Disc, DVD, and Bluray players cannot operate without them. In our industry, laser engraving is a revolution.

Laser engraving enables us to create highly detailed artwork onto various materials. This includes glass, plastics, coated and uncoated metals, plastics, and stone. The process consists of three parts:

- The Laser: without which, the process would be totally useless;

- A Controller: typically a computer or another device, like a Programmable Logic Controller;

- A Surface: for example, a Laser Table (also known as an X-Y Table).

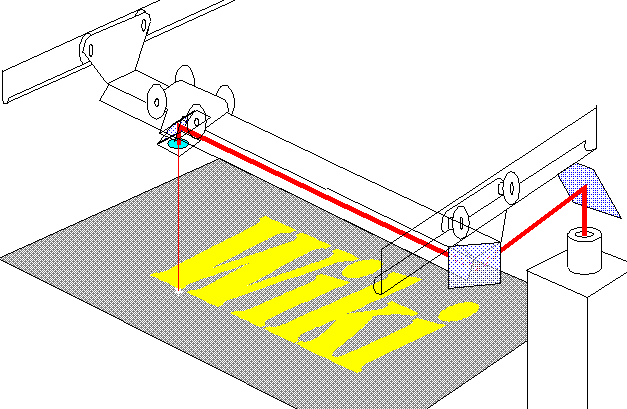

The X-Y Table plots around the lines of a copied image using the X and Y axes. The laser is often fixed to the sides of the table. Mirrors guide the laser light towards the exact position of the reproduced image.

How laser engraving works: this diagram shows you where the mirrors and laser light are typically placed. Image by Kittyslave (Public Domain).

Due to technological developments, laser engraving machines have gone smaller. As well as factory settings, you are just as likely to see them in key cutting shops and kiosks. Or on market stalls and barrows in local shopping precincts.

The amount of detail that is possible allows for more intricate designs. Trophies could have more intricate typefaces; plaques can be accompanied with flourishes on either side. Its flexibility is seldom rivalled.

We offer laser engraving services from our base near Gatwick Airport – all using the latest technology. The materials we use include Traffolyte, brass, and chrome. If you need a single plaque or several plaques engraving, why not contact us? You can telephone us on 01342 843211, or send an email to sales@able-engraving.co.uk. Whatever way you choose, we shall reply to you as soon as possible.

Able Engraving, 17 August 2016.